Aluminum Sectional Rail and Stile Doors

A full 3″ thick, the Raynor AV300 is the sturdiest door in the AlumaView family. The increased thickness adds strength and durability. With the incorporation of the U-bar trussing inside the rails, there are no obstructions to your view.

The AV300 is the clear choice for auto dealerships, car washes, corrosive environments, police, fire and ambulance stations, quick lubes, repair facilities, restaurants, marinas, sports facilities and buildings with large opening sizes.

AV300 Features and Options

Raynor AlumaView AV300 aluminum sectional rail and stile doors are available with numerous features and options, including those listed below.

Years of Durability

AlumaView door sections are clear-anodized for maximum durability and are designed to withstand minimum wind loads of 20 p.s.f. Higher pressure ratings are available upon request.

Rugged Hardware and Springs

Your AlumaView door comes packaged with the right combination of hardware, track and springs to match your door’s size and application.

Decreased Energy Costs

AlumaView doors help you reduce energy costs with a U-shaped, vinyl bottom weatherseal secured by a sturdy aluminum retainer.

Snap-in Retainer

AlumaView panels and glass are sealed and held in place with a snap-in retainer. Clear anodized, RAL9003, RAL 9016 and standard white doors use gray snap-ins. All other doors use black snap-ins.

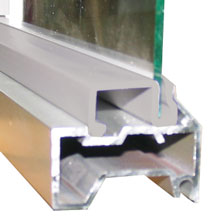

Integral U-Bar

Integral U-bar construction within the rails of the AV300 creates added strength to the section panels and provides for a clean look on the interior of the door by removing trussing obstructions from visible areas (only required for doors wider than 18’2″).

Header Seal

Flexible vinyl flap header seal reduces air infiltration and energy costs by sealing the top of the door against the header.

Jamb Seal

EPDM rubber jamb seal also helps to reduce air infiltration and decrease energy costs by sealing the side of the door when closed.

Choice of Windows

Available in impact glass, tempered, tinted, doublepane, insulated, acrylic, or polycarbonate in a variety of thicknesses. Glass thickness range from 1/8″ to 1″.

EnduraCote™

The Raynor EnduraCote hardware system comes with springs, track, and hardware that are powder coated to provide a clean, finished look and maximum protection against rust.

SleekSightline™

Our AV200 and AV300 models offer a sleek 1-pane or trendy 2-pane glass layout. These new glass layouts are available now and vary depending on glass type and door size.

Aluminum Panels

For busy work environments and to prevent glass breakage, aluminum panels protect your investment. Choose from insulated panels, kick panels and impact rated panels as well.

High-cycle Counterbalance System

For reliable operation in high traffic areas, choose high-cycle torsion springs with 25,000, 50,000, or 100,000-cycle life. For reduced maintenance and ultra-smooth operation in heavy-use applications, choose a weight counterbalance system.

Locks

Carbon Monoxide Vent

Allows you to channel fumes to the outside when the Raynor AlumaView door is closed. Available in a variety of sizes.

Customized Track*

Track systems are supplied to fit special clearances, inclines or contour applications. Hardware and track systems can be customized to fit any need. Additional trussing is available for special wind loading applications. A QuikClip™ pre-assembled track option is also available.

*Some options may be limited to door size or model.

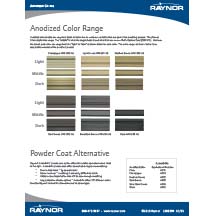

Anodized Finishes

Choose from six custom anodize finishes including champagne, light bronze, medium bronze, dark bronze, extra dark bronze, or black.

IECC Requirements Package/California Title 24

The International Energy Conservation Code (IECC) requires building components to meet minimum Air Infiltration rates. This option will ensure the AV300 and AV200 will exceed the latest IECC and Title 24 standards for air infiltration (only), by using the required header and jamb seals and track mounting. Exhaust ports and pass doors cannot be used. Visit our IECC page for more information.

Colors

Anodized Aluminum: Standard – Clear | Optional – Champagne, Black, or Light, Medium, Dark, or Extra Dark Bronze.

ArmorBrite™ Powder Coat System

Custom Colors: ArmorBrite: 188 custom powder coated colors available.

Product Details

| Door | ||

| Model | AlumaView AV300 | |

| Size | 24′ x 24′ Max | |

| Operation | Manual, Motor or Hand Chain | |

| IECC Thermal Performance | Tested Air Infiltration @ 25 mph 0.24 cfm/ft2 | |

| Sections | ||

| Construction | Rail & Stile – minimum .063″; 5/16″ diameter screws | |

| Material | Aluminum | |

| Surface Texture | Smooth | |

| Section Joint | Tongue and Groove | |

| Section Thickness | 3″ | |

| Gauge | N/A | |

| Stiles | Extruded aluminum – minimum .05″ | |

| Insulation | 3/8″ Expanded Polystyrene (in panels only) | |

| Seals | Bottom Seal (3″, 4″ Gray; 3″ Yellow; or 3″ Black EPDM), Optional Header Seal. Optional IECC and California Title 24 air filtration compliant package available. | |

| Trussing | Wind Load: 20 P.S.F. Tested/13.3 P.S.F. Design Load (standard); Material: U-bar (18-Gauge or 20-Gauge);Sizes: 4″, 6″, or 8″ | |

| Panel Configuration | .50″ thick Aluminum panels | |

| Color | Clear Anodized or Optional: ArmorBrite Powder Coat System 188 custom colors available, or Bronze Anodized, Black Anodized | |

| Windows | 1/8″ DSB Glass; 1/8″ 1/4″ 3/16″ Clear Tempered Glass; 1/8″ 1/4″ Tinted or Tinted Tempered Glass; 3/16″ 1/4″ Clear Glass; 1/4″ Clear Laminated Glass; 1/4″ Clear Wire Glass; 1/2″ Insulated DSB Glass; 1” glass available in Insulated Clear, Insulated Clear Tempered, Insulated Low E Annealed, Insulated Low E Tempered, Insulated Satin Tempered, and Special Glass Available for Order (Please Note: 1” Insulated Glass is Made up of Two Panes of 1/8” Glass with a ¾” air space.) | |

| Track | ||

| Type | Normal Headroom, Rear Mount Low Headroom, Front Mount Low Headroom, Lift Clearance, Vertical Lift, Incline, Contour, and QuikClip™ Pre-Assembled Track Options | |

| Finish | Galvanized or Optional White Powder Coat | |

| Size | 2″ or 3″ | |

| Gauge | 13 and 16-Gauge | |

| Counterbalance System | ||

| Type | Torsion Spring, Tandem Shaft Torsion Spring, or Weight Counterbalance | |

| Springs | Spring Inner Diameter: 2-1/4″, 3-1/2″ or 5-1/2″; Duplex or High Cycle (30K, 50K, 100K); Optional Black Powder Coat | |

| Shafts | Tube or Solid (D-Shaft, 1″ Keyed, 1-1/4″ Keyed) | |

| Hardware/Accessories | ||

| Hinges | 11, 13, 14-Gauge or Hybrid | |

| Rollers | Standard (2″ or 3″) or Heavy Duty (2″ or 3″) | |

| Finish | Galvanized or Optional White Powder Coat | |

| Lock | Interior Slide Lock or Exterior Lock Bars | |

| Seal(s) | Jamb Seal | |

| Hanger Angle | 11, 13-Gauge Galvanized or 13-Gauge White Powder Coated | |

| Pedestrian Door | NA | |

| Optional Wind Loading | Certified Wind Load Available | |

Specifications and Drawings

| Specifications | Word Document | PDF document |

| Raynor Quick Spec | Microsoft Word Document | PDF Document |

| CSI Master Format | Microsoft Word Document | PDF Document |

Standard Drawings

| 2-inch Track/Bracket-Mounted | ||

| Normal Headroom | DWG Drawing | Adobe PDF Document |

| Lift Clearance | DWG Drawing | Adobe PDF Document |

| Vertical Lift | DWG Drawing | Adobe PDF Document |

| Low Headroom Front-Mount | DWG Drawing | Adobe PDF Document |

| Low Headroom Rear-Mount | DWG Drawing | Adobe PDF Document |

| 2-inch Track/Angle-Mounted | ||

| Normal Headroom | DWG Drawing | Adobe PDF Document |

| Lift Clearance | DWG Drawing | Adobe PDF Document |

| Vertical Lift | DWG Drawing | Adobe PDF Document |

| Low Headroom Front-Mount | DWG Drawing | Adobe PDF Document |

| Low Headroom Rear-Mount | DWG Drawing | Adobe PDF Document |

| 3-inch Track/Angle-Mounted | ||

| Normal Headroom | DWG Drawing | Adobe PDF Document |

| Lift Clearance | DWG Drawing | Adobe PDF Document |

| Vertical Lift | DWG Drawing | Adobe PDF Document |

| Low Headroom Front-Mount | DWG Drawing | Adobe PDF Document |

| Low Headroom Rear-Mount | DWG Drawing | Adobe PDF Document |

Technical Information

Section and Panel Schedules

| Door Width | Number of Panels | Door Height | Number of Sections | |

|---|---|---|---|---|

| Up to 9’2″ | 2 | Up to 8’2″ | 4 | |

| 9′ 3″ – 12′ 2″ | 3 | 8′ 3″ – 10′ 6″ | 5 | |

| 12′ 3″ – 16′ 2″ | 4 | 10′ 7″ – 12′ 6″ | 6 | |

| 16′ 3″ – 20′ 2″ | 5 | 12′ 7″ – 14′ 6″ | 7 | |

| 20′ 3″ – 24′ 2″ | 6 | 14′ 7″ – 16′ 6″ | 8 |

AlumaView Warranty

Door Sections

Raynor® warrants the door sections against defects in material and workmanship for five (5) years from date of delivery to the original purchaser. Window components are warranted against defects in material and workmanship for three (3) years from date of delivery to the original purchaser.

Hardware and Springs

Raynor warrants all hardware and spring components against defects in material and workmanship for one (1) year from date of delivery to the original purchaser.

ARMORBRITE™

Doors equipped with AmorBrite powdercoat carry a warranty against cracking or peeling (losing adhesion) for three (3) years from date of delivery to the original purchaser.

WARRANTY LIMITATIONS and EXCLUSIONS

Under the terms of this limited warranty, for any door components that are found to be defective upon inspection by authorized Raynor personnel, Raynor will, at its option, repair or replace the defective door components. Labor charges for the installation or repairs shall be the responsibility of the consumer and must be performed by a qualified installer. This warranty applies only to doors that are professionally installed by a qualified installer.

This warranty extends only to the original purchaser, provided the door is installed in his/her place of business. This warranty is not transferable.

This warranty does not apply to any damage or deterioration to the door caused by abuse, negligence, missing components, accidents, use of pressure washers, dents or scratches. Shavings from trolley rails not properly removed and cleaned from the exterior door surface causing rust are not covered by this warranty. Failure to provide proper maintenance voids this warranty. Field applied paint failure is not covered by this warranty. Refer to the Care and Maintenance Instructions and Painting Instructions.

This warranty does not apply to damage caused by fire, an act of God, accident, vandalism or graffiti. Damage or deterioration caused by saltwater coastal areas (within two miles), hazardous or corrosive chemicals and fumes including, but not limited to, alkaline, acids, muriatic acids, road salt or salt environments, harsh cleaning agents, and fertilizers is not covered by this warranty.

Raynor shall not be liable for any consequential or incidental damages.

ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANT OF MERCHANTABILITY, ARE HEREBY EXPRESSLY EXCLUDED.

Some states do not allow the exclusion or limitation of consequential or incidental damages, so the above limitation or exclusion may not apply to you.

Claims for defects in material and workmanship covered by this warranty shall be made in writing with proof of purchase and photographs of the product in question to the dealer from whom the product was purchased or call Raynor at 1-800-4-RAYNOR within the warranty period. Raynor may choose to have the product returned for inspection.

This warranty gives you specific legal rights. You may also have other rights, which may vary from state to state.

Colors

Anodized Aluminum: Standard – Clear | Optional – Champagne, Black, or Light, Medium, Dark, or Extra Dark Bronze.

ArmorBrite™ Powder Coat System

Custom Colors: ArmorBrite: 188 custom powder coated colors available.

Product Details

| Door | ||

| Model | AlumaView AV300 | |

| Size | 24′ x 24′ Max | |

| Operation | Manual, Motor or Hand Chain | |

| IECC Thermal Performance | Tested Air Infiltration @ 25 mph 0.24 cfm/ft2 | |

| Sections | ||

| Construction | Rail & Stile – minimum .063″; 5/16″ diameter screws | |

| Material | Aluminum | |

| Surface Texture | Smooth | |

| Section Joint | Tongue and Groove | |

| Section Thickness | 3″ | |

| Gauge | N/A | |

| Stiles | Extruded aluminum – minimum .05″ | |

| Insulation | 3/8″ Expanded Polystyrene (in panels only) | |

| Seals | Bottom Seal (3″, 4″ Gray; 3″ Yellow; or 3″ Black EPDM), Optional Header Seal. Optional IECC and California Title 24 air filtration compliant package available. | |

| Trussing | Wind Load: 20 P.S.F. Tested/13.3 P.S.F. Design Load (standard); Material: U-bar (18-Gauge or 20-Gauge);Sizes: 4″, 6″, or 8″ | |

| Panel Configuration | .50″ thick Aluminum panels | |

| Color | Clear Anodized or Optional: ArmorBrite Powder Coat System 188 custom colors available, or Bronze Anodized, Black Anodized | |

| Windows | 1/8″ DSB Glass; 1/8″ 1/4″ 3/16″ Clear Tempered Glass; 1/8″ 1/4″ Tinted or Tinted Tempered Glass; 3/16″ 1/4″ Clear Glass; 1/4″ Clear Laminated Glass; 1/4″ Clear Wire Glass; 1/2″ Insulated DSB Glass; 1” glass available in Insulated Clear, Insulated Clear Tempered, Insulated Low E Annealed, Insulated Low E Tempered, Insulated Satin Tempered, and Special Glass Available for Order (Please Note: 1” Insulated Glass is Made up of Two Panes of 1/8” Glass with a ¾” air space.) | |

| Track | ||

| Type | Normal Headroom, Rear Mount Low Headroom, Front Mount Low Headroom, Lift Clearance, Vertical Lift, Incline, Contour, and QuikClip™ Pre-Assembled Track Options | |

| Finish | Galvanized or Optional White Powder Coat | |

| Size | 2″ or 3″ | |

| Gauge | 13 and 16-Gauge | |

| Counterbalance System | ||

| Type | Torsion Spring, Tandem Shaft Torsion Spring, or Weight Counterbalance | |

| Springs | Spring Inner Diameter: 2-1/4″, 3-1/2″ or 5-1/2″; Duplex or High Cycle (30K, 50K, 100K); Optional Black Powder Coat | |

| Shafts | Tube or Solid (D-Shaft, 1″ Keyed, 1-1/4″ Keyed) | |

| Hardware/Accessories | ||

| Hinges | 11, 13, 14-Gauge or Hybrid | |

| Rollers | Standard (2″ or 3″) or Heavy Duty (2″ or 3″) | |

| Finish | Galvanized or Optional White Powder Coat | |

| Lock | Interior Slide Lock or Exterior Lock Bars | |

| Seal(s) | Jamb Seal | |

| Hanger Angle | 11, 13-Gauge Galvanized or 13-Gauge White Powder Coated | |

| Pedestrian Door | NA | |

| Optional Wind Loading | Certified Wind Load Available | |

Specifications and Drawings

| Specifications | Word Document | PDF document |

| Raynor Quick Spec | Microsoft Word Document | PDF Document |

| CSI Master Format | Microsoft Word Document | PDF Document |

Standard Drawings

| 2-inch Track/Bracket-Mounted | ||

| Normal Headroom | DWG Drawing | Adobe PDF Document |

| Lift Clearance | DWG Drawing | Adobe PDF Document |

| Vertical Lift | DWG Drawing | Adobe PDF Document |

| Low Headroom Front-Mount | DWG Drawing | Adobe PDF Document |

| Low Headroom Rear-Mount | DWG Drawing | Adobe PDF Document |

| 2-inch Track/Angle-Mounted | ||

| Normal Headroom | DWG Drawing | Adobe PDF Document |

| Lift Clearance | DWG Drawing | Adobe PDF Document |

| Vertical Lift | DWG Drawing | Adobe PDF Document |

| Low Headroom Front-Mount | DWG Drawing | Adobe PDF Document |

| Low Headroom Rear-Mount | DWG Drawing | Adobe PDF Document |

| 3-inch Track/Angle-Mounted | ||

| Normal Headroom | DWG Drawing | Adobe PDF Document |

| Lift Clearance | DWG Drawing | Adobe PDF Document |

| Vertical Lift | DWG Drawing | Adobe PDF Document |

| Low Headroom Front-Mount | DWG Drawing | Adobe PDF Document |

| Low Headroom Rear-Mount | DWG Drawing | Adobe PDF Document |

Technical Information

Section and Panel Schedules

| Door Width | Number of Panels | Door Height | Number of Sections | |

|---|---|---|---|---|

| Up to 9’2″ | 2 | Up to 8’2″ | 4 | |

| 9′ 3″ – 12′ 2″ | 3 | 8′ 3″ – 10′ 6″ | 5 | |

| 12′ 3″ – 16′ 2″ | 4 | 10′ 7″ – 12′ 6″ | 6 | |

| 16′ 3″ – 20′ 2″ | 5 | 12′ 7″ – 14′ 6″ | 7 | |

| 20′ 3″ – 24′ 2″ | 6 | 14′ 7″ – 16′ 6″ | 8 |

AlumaView Warranty

Door Sections

Raynor® warrants the door sections against defects in material and workmanship for five (5) years from date of delivery to the original purchaser. Window components are warranted against defects in material and workmanship for three (3) years from date of delivery to the original purchaser.

Hardware and Springs

Raynor warrants all hardware and spring components against defects in material and workmanship for one (1) year from date of delivery to the original purchaser.

ARMORBRITE™

Doors equipped with AmorBrite powdercoat carry a warranty against cracking or peeling (losing adhesion) for three (3) years from date of delivery to the original purchaser.

WARRANTY LIMITATIONS and EXCLUSIONS

Under the terms of this limited warranty, for any door components that are found to be defective upon inspection by authorized Raynor personnel, Raynor will, at its option, repair or replace the defective door components. Labor charges for the installation or repairs shall be the responsibility of the consumer and must be performed by a qualified installer. This warranty applies only to doors that are professionally installed by a qualified installer.

This warranty extends only to the original purchaser, provided the door is installed in his/her place of business. This warranty is not transferable.

This warranty does not apply to any damage or deterioration to the door caused by abuse, negligence, missing components, accidents, use of pressure washers, dents or scratches. Shavings from trolley rails not properly removed and cleaned from the exterior door surface causing rust are not covered by this warranty. Failure to provide proper maintenance voids this warranty. Field applied paint failure is not covered by this warranty. Refer to the Care and Maintenance Instructions and Painting Instructions.

This warranty does not apply to damage caused by fire, an act of God, accident, vandalism or graffiti. Damage or deterioration caused by saltwater coastal areas (within two miles), hazardous or corrosive chemicals and fumes including, but not limited to, alkaline, acids, muriatic acids, road salt or salt environments, harsh cleaning agents, and fertilizers is not covered by this warranty.

Raynor shall not be liable for any consequential or incidental damages.

ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANT OF MERCHANTABILITY, ARE HEREBY EXPRESSLY EXCLUDED.

Some states do not allow the exclusion or limitation of consequential or incidental damages, so the above limitation or exclusion may not apply to you.

Claims for defects in material and workmanship covered by this warranty shall be made in writing with proof of purchase and photographs of the product in question to the dealer from whom the product was purchased or call Raynor at 1-800-4-RAYNOR within the warranty period. Raynor may choose to have the product returned for inspection.

This warranty gives you specific legal rights. You may also have other rights, which may vary from state to state.